Ever been told that steel framing is automatically bad because it has poor thermal performance? Let's break down why that is not necessarily true and what modern methods are available that help improve its performance.

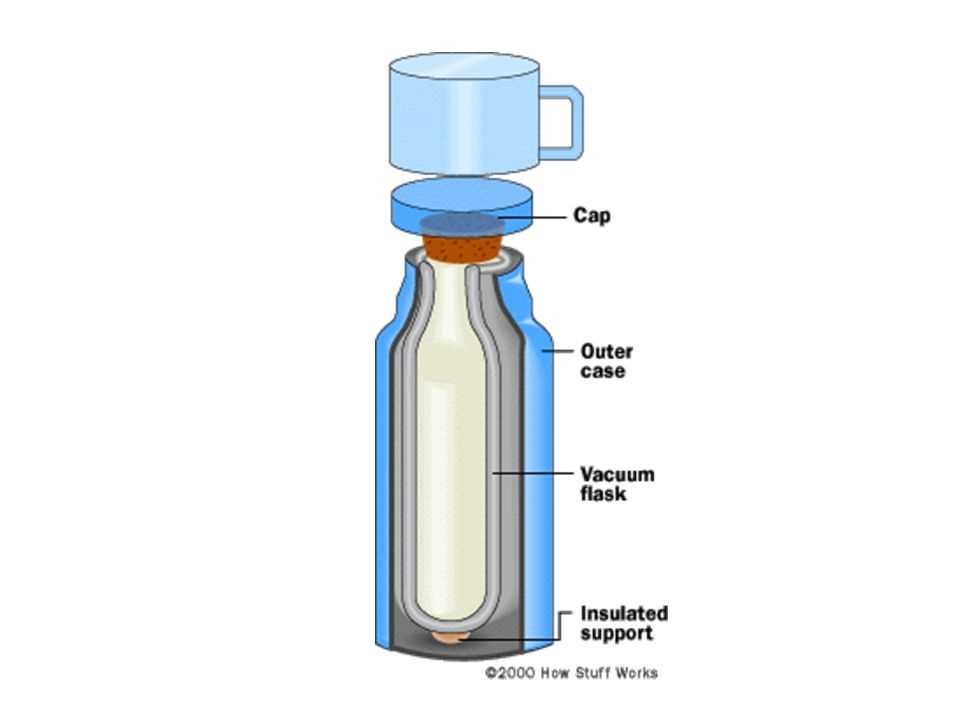

The Thermos Flask Analogy: Why One Number Doesn't Tell the Whole Story

Yes steel framing does have high thermal conductivity when compared to timber (45.000 W/(mK) vs 0.130 W/(mK)). But here's the thing: a wall isn't just one material. Think of it like a thermos flask. The stainless steel inner wall conducts heat really well, but you don't feel your hot coffee through the outer wall because there's insulation and an air gap in between. Same with walls—how the whole system works together matters more than just one component.

When you test a real wall (not just a steel stud by itself), the performance depends on:

- How far apart the studs are spaced

- What insulation fills the gaps

- Whether there's a thermal break on the outside

- The plasterboard, air films, and cladding

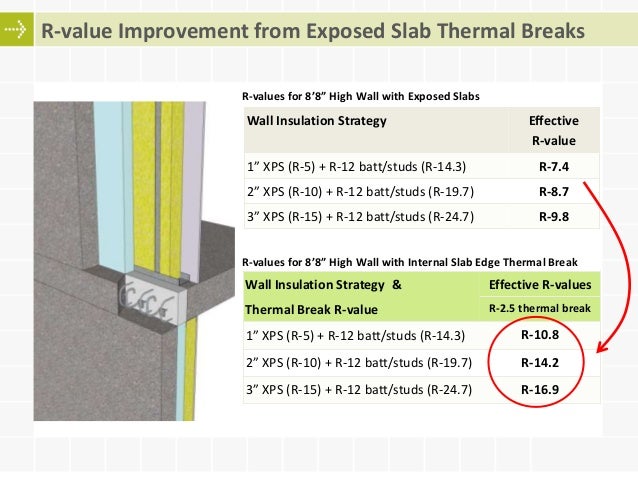

A steel-framed wall with no thermal break might only achieve R1.36. Add a simple 12mm foam strip behind the cladding (called a thermal break), and suddenly you're back up to R2.45—that's an 80% improvement! Add a thicker 25mm strip and you hit R2.69, which is only 14% away from the theoretical "perfect" wall.

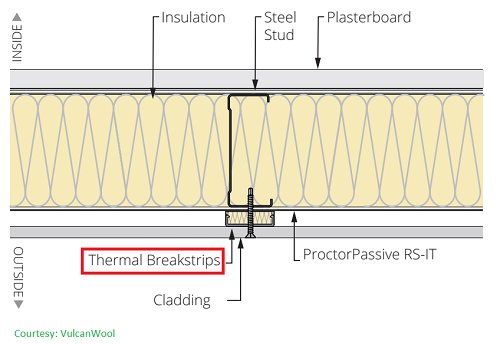

What is a Thermal Break?

Thermal breaks are materials with low thermal conductivity placed between highly conductive structural components in buildings to reduce heat transfer. They're basically strips of foam or timber placed between the steel frame and the outside cladding. Imagine you're trying to drive fast down a highway, but every few meters there's a speed bump. You'll slow right down. That's exactly what a thermal break does to heat trying to flow through steel—it interrupts the fast pathway and forces heat to take the slow route through insulation instead.

Houses in New Zealand and Australia using thermal breaks routinely pass building codes and energy ratings. Projects targeting Passive House certification (the gold standard for energy efficiency) achieve their ratings with steel frames when thermal breaks are properly installed.

The Condensation Scare: It's About Temperature, Not Materials

"Steel encourages condensation and mold" — this sounds scary, but it's missing context. Condensation happens when a surface gets cold enough that moisture in the air turns to water droplets (like your bathroom mirror after a hot shower).

Here's the key: any wall surface below 16°C can get condensation, whether it's steel or timber behind it. The difference is that with a thermal break, the steel stays on the cold side of the wall, and the interior plasterboard stays warm and dry. Modern steel-framed homes with thermal breaks maintain interior surface temperatures well above 16°C, even in Queenstown, New Zealand winters (where it can get past -2°C!).

The Bottom Line: It's About Good Design, Not Material Prejudice

Concerns about thermal conductivity and condensation are valid—but they're solvable problems, not insurmountable barriers. Dismissing steel entirely because it conducts heat is like dismissing concrete because it's heavy, or timber because it burns. Every material has challenges; good designers work around them. When properly detailed with thermal breaks, steel-framed homes can be just as energy-efficient, comfortable, and code-compliant as timber homes—while offering superior durability, pest resistance, and fire safety.

Sources

- Energy Compliance ConsultantsEnergy Compliance is subsidiary & energy assessment arm of GeoHeat Australia Pty Ltd.

- LinkedInThermal Breaks for Steel Framing: How to Prevent Condensation and Heat Loss in NZ Homes

- build.com.auAn independent construction resource comparing the technical merits of timber and steel framing, including noise and thermal performance.