Jump to Section

Our standard homes provide a comprehensive, all-inclusive package that covers every stage from concept to completion. We handle all the necessary plans, and drawings needed for approval for a streamlined process. View the handbook below to see the vast selection of finishes available. Upgrades are available at each stage.

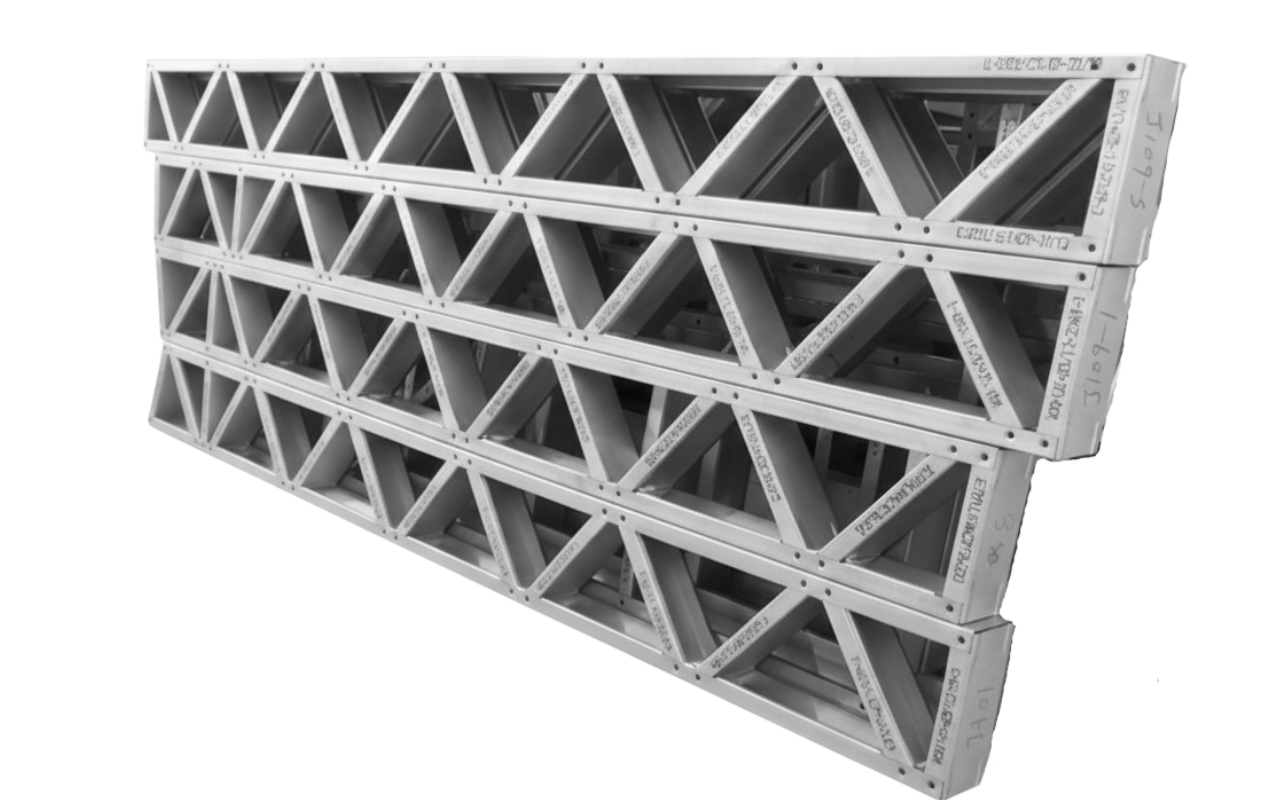

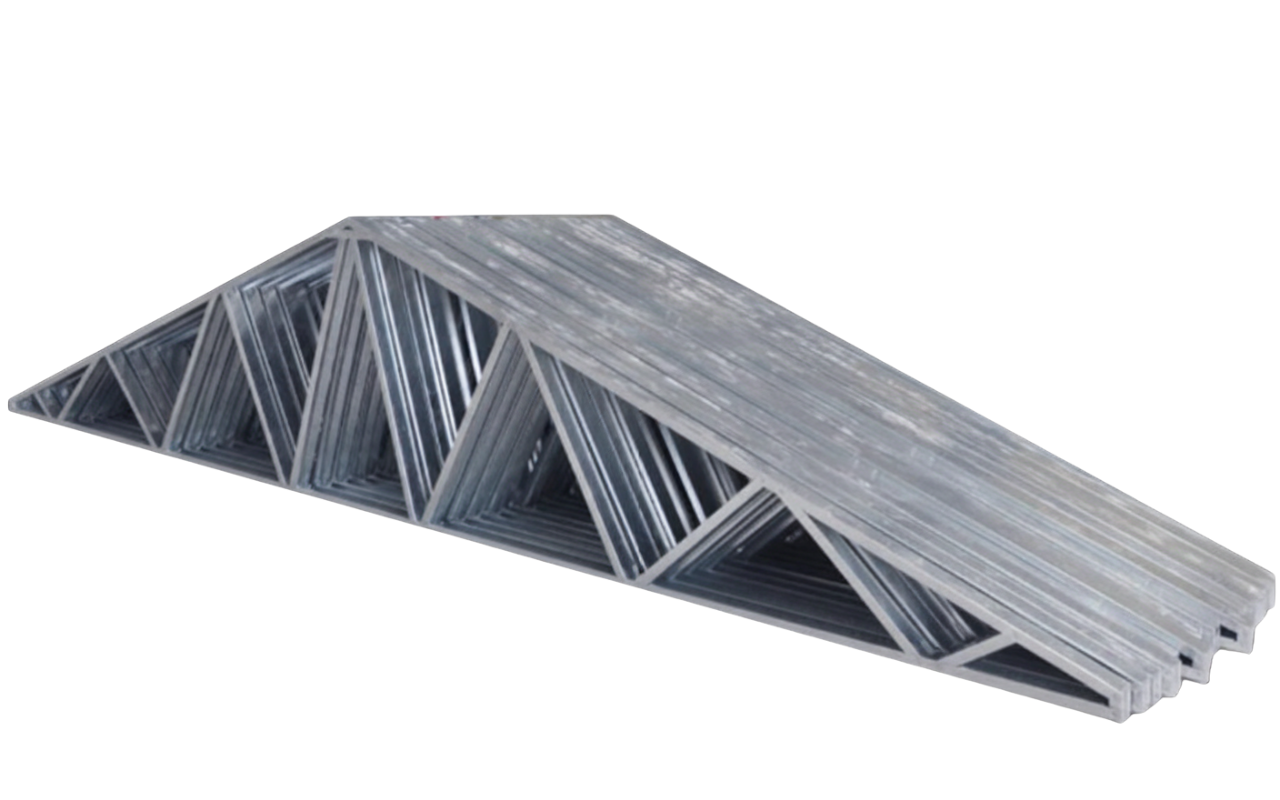

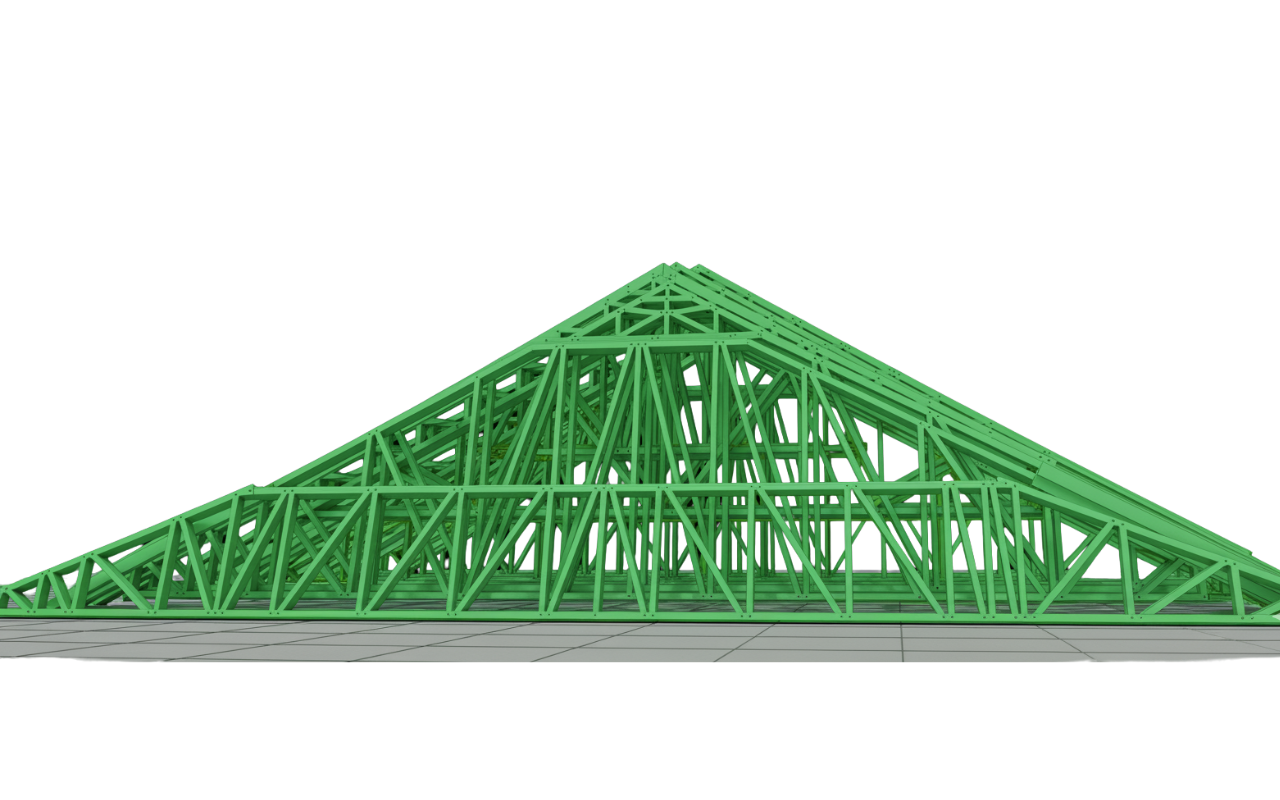

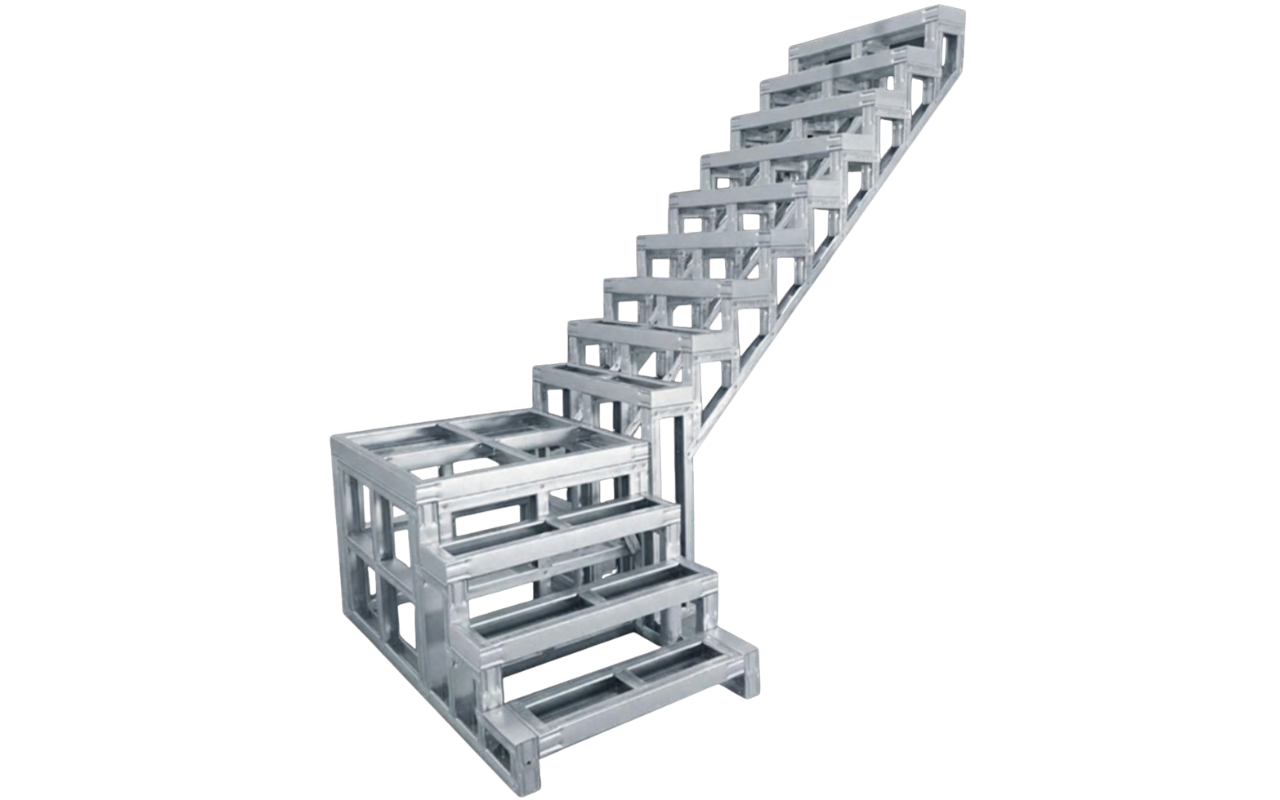

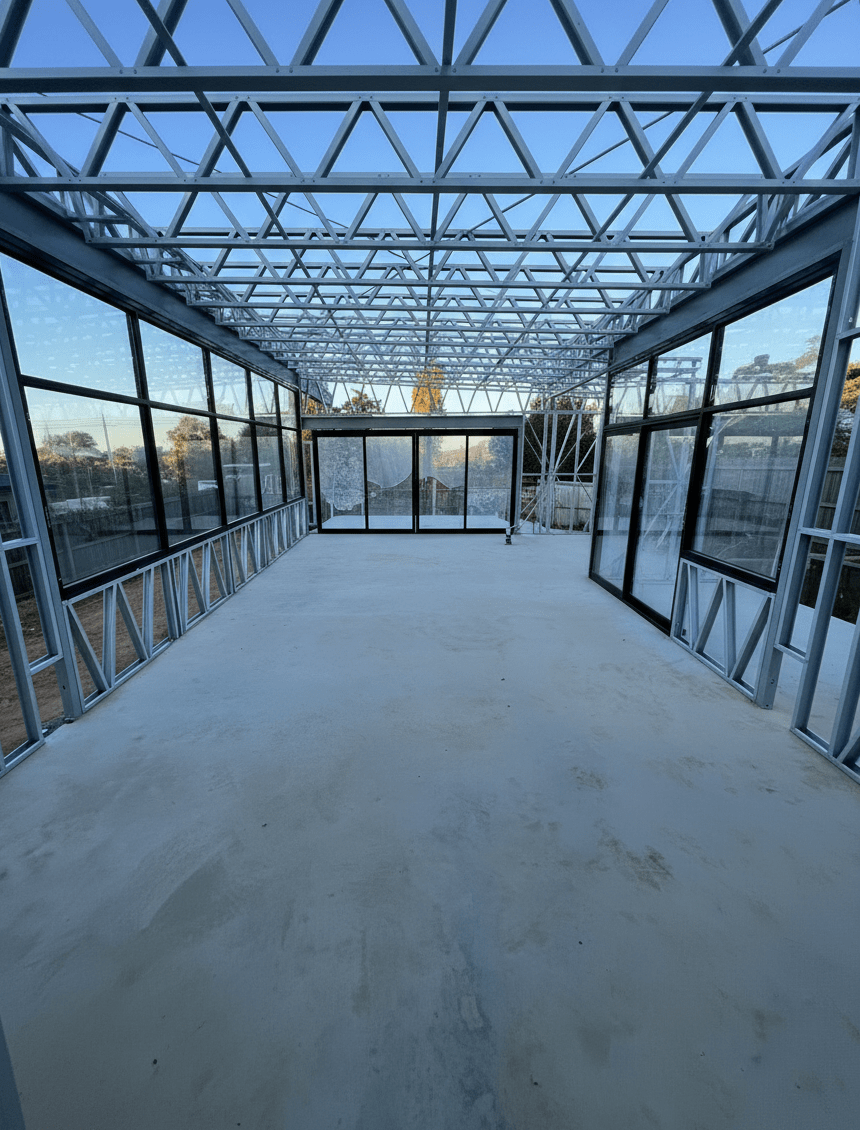

Core Framing Components

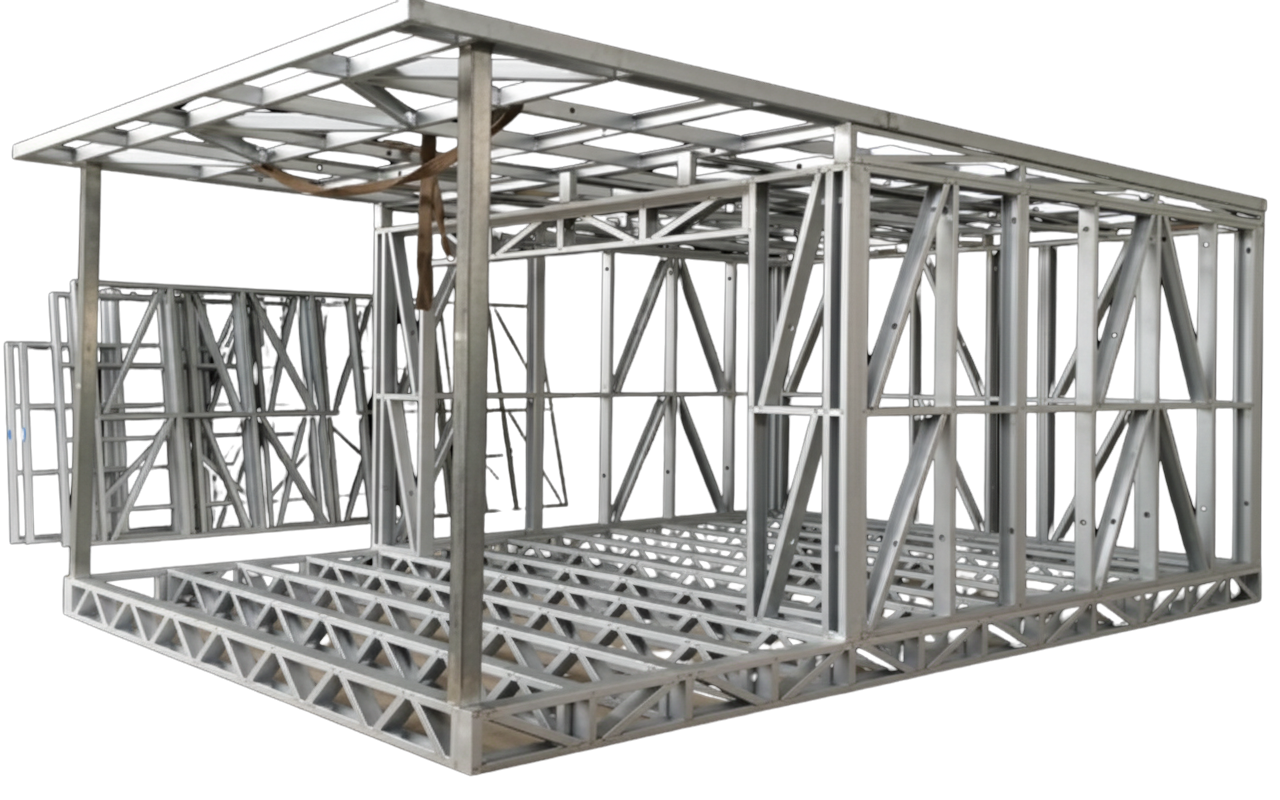

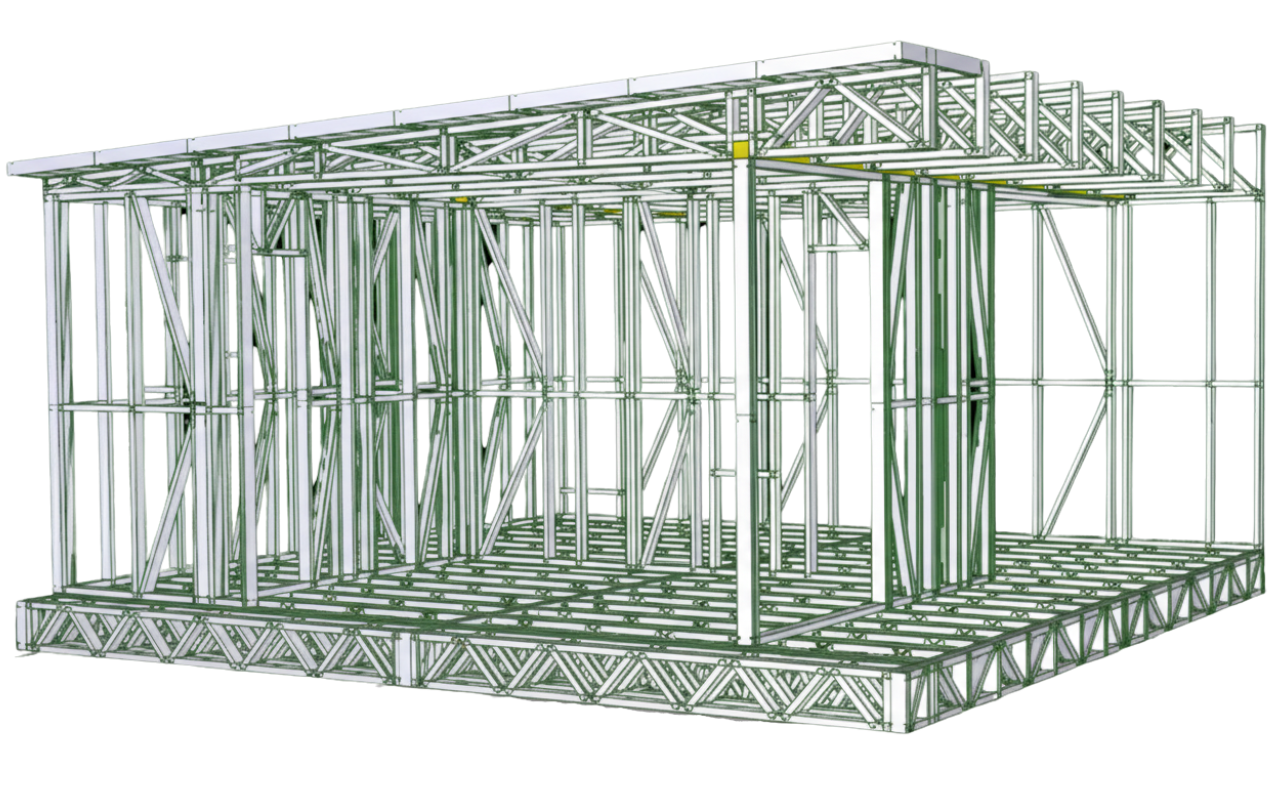

A home’s foundation begins with strength, flexibility, and performance—delivered through your choice of light-gauge steel. From compact granny flats to expansive bespoke homes, Zen Sanctuary LGS framing offers the ideal solution, providing the strength, durability, and longevity your home deserves. The technical details below outline our standard wall framing, floor systems, roof trusses, and core components included in each kit. Have a design that falls outside the specifications listed? Connect with our friendly team, and we’ll work with you to engineer and supply the perfect solution for your project.

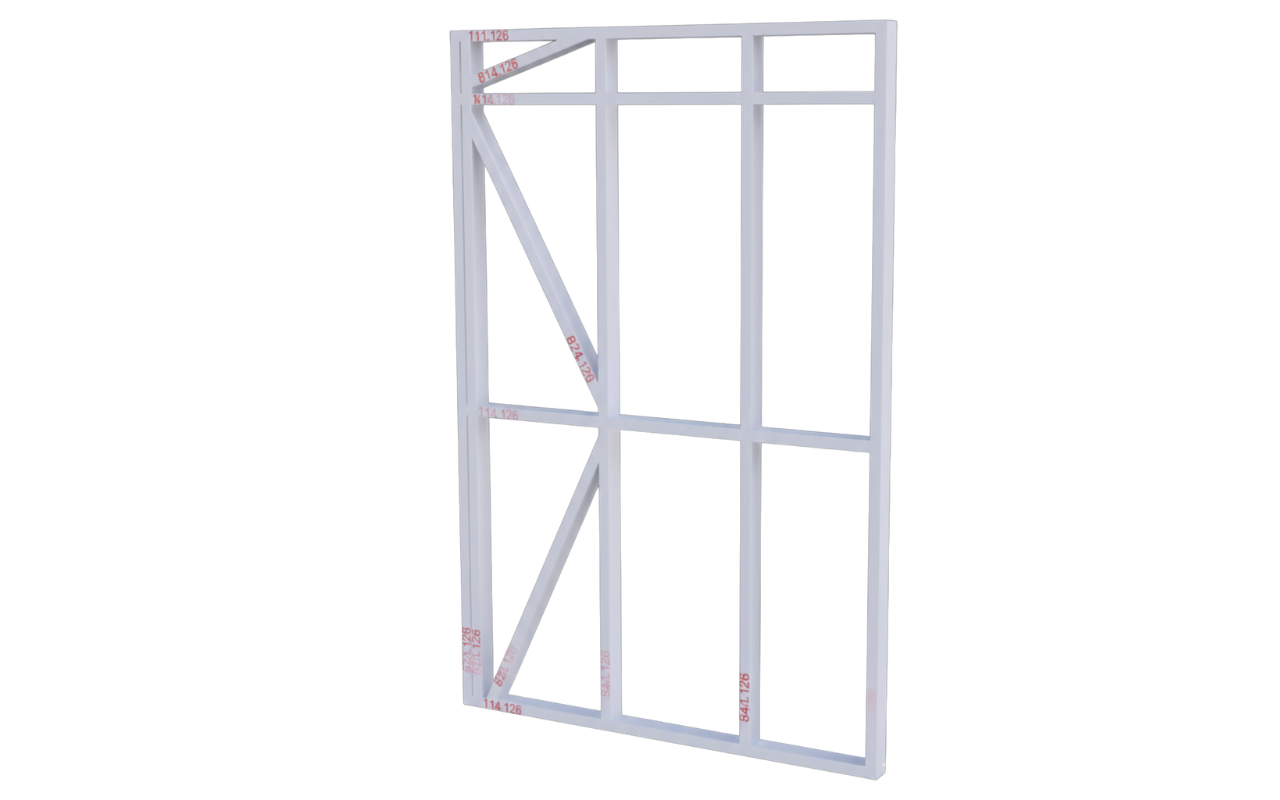

Wall Frames

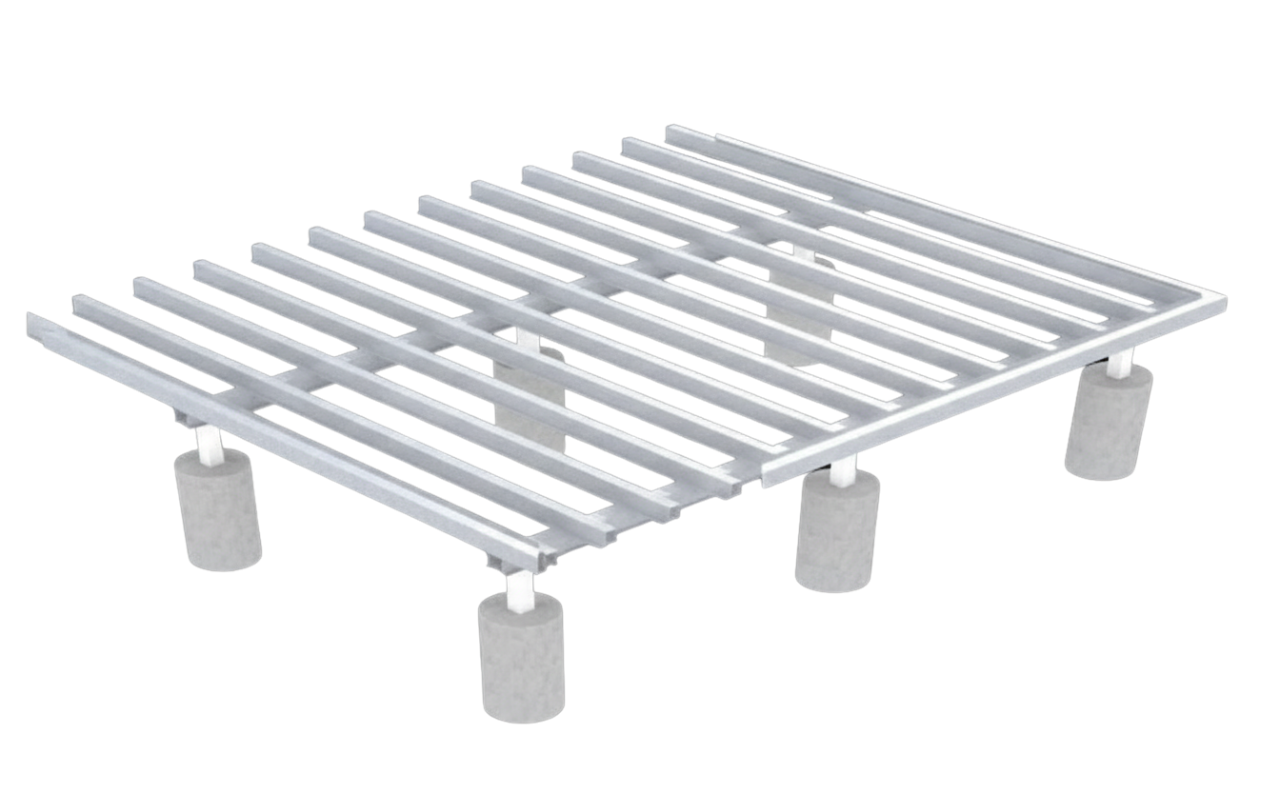

Floor Systems

Roof & Trusses

Core Components

From The Journal

Breaking the “Steel = Bad” Myth: How a Tiny Thermal Break Makes a Big Difference

Ever been told that steel framing is automatically bad because it has poor thermal performance? Let's break down why that is not necessarily true and what modern methods are available that help improve its performance.

Read More

The Ultimate Guide to Granny Flat Regulations in Australia (2025 Update)

A secondary dwelling, or granny flat, is a powerful way to unlock the potential of your property. Whether for family, rental income, or a private retreat, the journey begins with a clear understanding of the rules.

Read More

A Project Managers Guide for the Australian Owner Builder

Being an owner-builder in Australia offers an incredibly hands-on and rewarding path to creating a dream home or executing a major renovation, here’s how to master the essential project management side—no need to hire an external project manager.

Read MoreFrequently Asked Questions

What are the benefits of Light-Gauge Steel framing compared to traditional timber?

Light-Gauge Steel (LGS) framing offers numerous advantages over timber, including non-combustibility, termite resistance, dimensional stability, and superior strength-to-weight ratio. LGS frames don't warp or shrink over time, eliminating plaster cracks and sticking doors. They're also eco-friendly, recyclable, and allow for more open floor plans due to their structural strength.

Does LGS framing squeak due to thermal expansion?

Light Gauge Steel (LGS) framing does not typically squeak. Unlike timber (which can shrink or swell 10–15 times more across the grain), it does not warp or shrink with changes in humidity and the movement is uniform and controlled through proper fastening. Any noise in a steel-framed building is usually caused by floorboards, sheeting, or other finishes interacting with the frame, rather than the steel itself. While steel does expand and contract slightly (i.e., A 3-meter member would move only about 1.4 mm) with temperature, LGS systems are designed with screws, slots, and detailing that accommodate this small movement. With correct installation, LGS frames remain quiet, stable, and durable.

What kind of warranty do you provide on materials and construction?

We stand behind our materials and construction with comprehensive warranty coverage. The Light-Gauge Steel frames are rated for an 80-year lifespan and come with a 10-year structural warranty. All installed appliances, fixtures, and systems carry their respective manufacturer warranties.